Advantages of glass bottle packaging for cosmetics

1. Protecting active ingredients: Glass has an opaque material that has a good blocking effect on light. This enables the glass bottle to effectively protect the active ingredients in essence from the influence of light and air, which helps to extend the stability and shelf life of the product.

2. Recyclability: Glass is a recyclable material that conforms to the trends of sustainability and environmental protection. Most places have glass recycling facilities, so using glass bottles can help reduce environmental burdens.

3. High quality texture: Cosmetic glass bottles have a noble and elegant appearance, giving products a high quality texture. The texture and transparency of this material allow consumers to visually see the product, increasing its attractiveness when making a purchase.

4. Chemical resistance: Glass has a high resistance to chemicals and is not easily affected by cosmetic ingredients, ensuring the purity and stability of the product.

5. Precise pump design: glass essence bottles are usually equipped with high-quality pumps or droppers, which can ensure that an appropriate amount of products can be accurately distributed each time they are used to avoid waste.

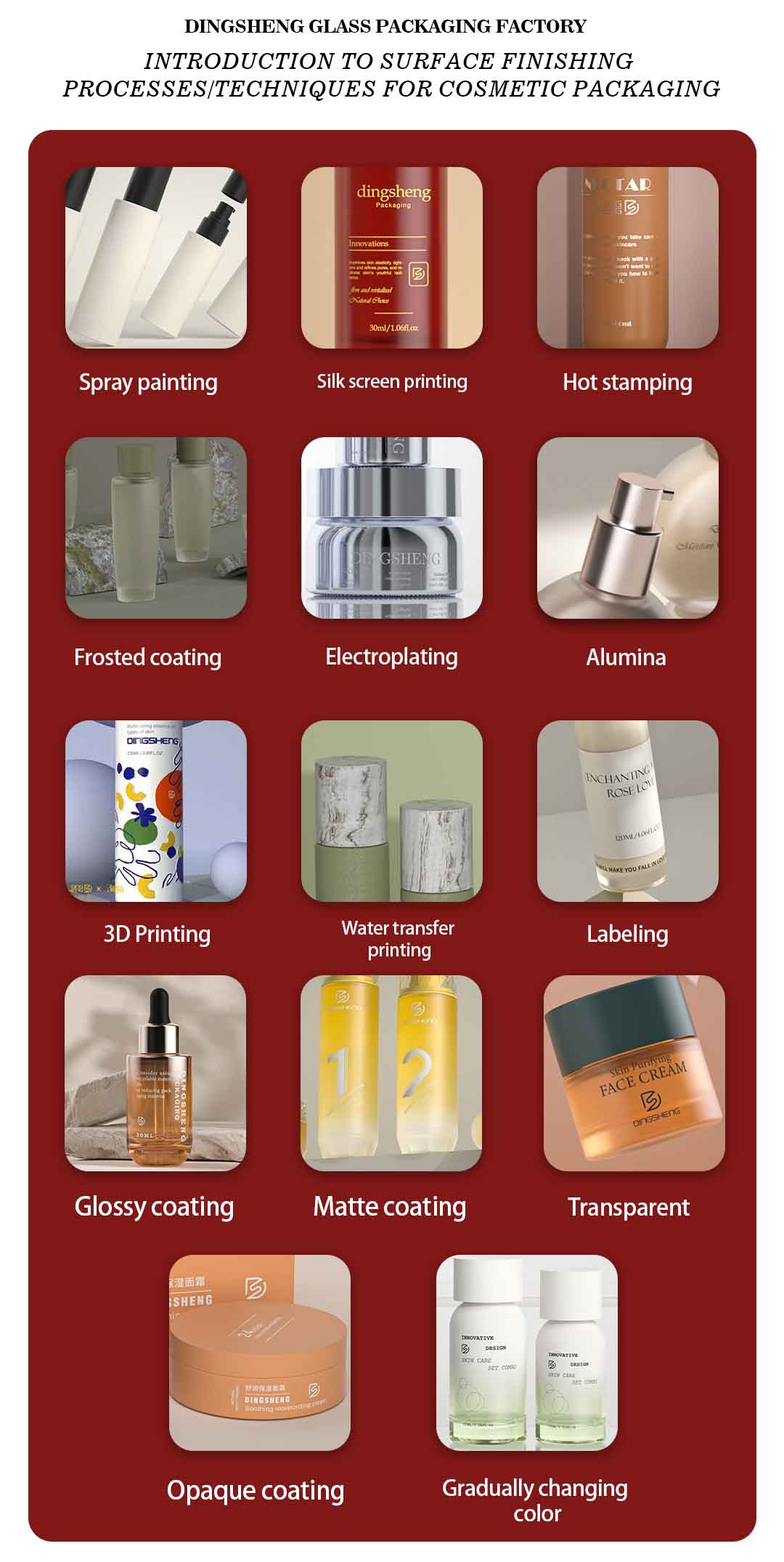

6. Customizable design: Brands can design unique skincare glass bottles based on product positioning and target market needs, highlighting the brand's uniqueness and high-end feel.